Pipe Fittings

- Buttweld Fittings

-

- Equal Tee

- Reducing Tee

- Equal Cross

- Reducing Cross

- Reducers

- Concentric Reducer

- Eccentric Reducer

- Pipe Cap

- End Cap

- Collar

- Swedge Nipple

- Pipe Nipples

- Barrel Nipple

- Reducing Nipple

- 90° Long Radius Elbow

- 90° Short Radius Elbow

- 45° Long Radius Elbow

- 45° Short Radius Elbow

- 180° Long Radius Elbow

- 180° Short Radius Elbow

- 1D Elbow

- 1.5D Elbow

- 3D Elbow

- 5D Elbow

- Seamless Buttwelding 45° and 90° Elbows

- Welded Elbows

- Seamless Buttweld 180° Returns

- straight tees and crosses

- Reducing Outlet Tees and Reducing Outlet Crosses

- Stub End

- Lap Joint Stub Ends

- Long Stub End

- Short Stub End

- Bend

- Long Radius Bend

- Piggable Bend

- Lateral Tee

- Forged Fittings

- Threaded Fittings

- Socket Weld Fittings

- Materials

WE EXPORT TO

Sarda Pipes & Fittings can manufacture and supply Stub End in standard sizes, as well as in accordance with specification of our customers.

Buttweld Stub End | ASTM A403 ASME SA403 Stainless Steel Buttweld Stub End | ASTM A234 Carbon Steel Buttweld Stub End | ASME B16.9 Buttweld Stub End Manufacturers Exporters India | Alloy Steel Buttweld Stub End .

Sarda Pipes & Fittings is a leading Manufacturer, Exporter and Supplier of Stub End . Buttweld Stub End manufactured using superior grade raw materials. Sarda Pipes & Fittings supply steel stainless steel and high quality products to international like ULMA companies and international stockholders in the United States, Europe, Russia, Turkey, Malaysia, the UAE, Saudi Arabia, Iran, Brazil, Chile, Mexico, South Africa, Jordan, Tunisia, Vietnam, Indonesia, Thailand, Singapore, Colombia, and Sri Lanka.

An elbow is a pipe fitting which is used as a connection point between two lengths of pipes to produce a change in the direction of flow in the pipe, usually at an angle of 90°. Elbows are also commonly referred as bends and are available in a range of materials such as stainless steel, carbon steel, alloy steel, nickel alloys, duplex, and cupro nickel.

Buttweld Stub End , ASTM A403 ASME SA403 Stainless Steel Buttweld Stub End , ASTM A 234 Carbon Steel Buttweld Stub End , ASME B16.9 Buttweld Stub End , Alloy Steel Buttweld Stub End Manufacturers And Suppliers in India. Stub End | ASTM A403 ASME SA403 Stainless Steel Stub End | ASTM A 234 Carbon Steel Stub End | ASME B16.9 Stub End Manufacturers Exporters India | Alloy Steel Stub End

|

|

| Type | : | Butt weld (BW) |

| Standards | : | ASME / ANSI - B 16.9 ASTM A403 - ASME SA403 - 'Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings' API 590-605 ASME B16.9 - 'Factory-Made Wrought Buttwelding Fittings' ASME B16.25 - 'Buttwelding Ends' ASME B16.28 - 'Wrought Steel Buttwelding Short Radius Elbows and Returns' MSS SP-43 - 'Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications' |

| Dimension | : | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| Thickness | : | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Schedule | : | Sch 5 TO Sch XXS. |

| Size | : | 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”) |

Materials and Grade:

Stainless Steel Stub End :

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Stub End :

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Stub End :

Inconel 600 & 625,

Incolloy 800, 825,

Hastelloy C22, C276,

Hastelloy,

Nickel,

Monel,

Inconel,

Alloy20,

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

| Size : 1/8"NB TO 48"NB IN | ||||||||||||

| Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS | ||||||||||||

| Type : Seamless / ERW / Welded / Fabricated | ||||||||||||

| Form : Long Stub End & Short Stub End | ||||||||||||

| Materials : Long Stub End & Short Stub End | ||||||||||||

| Stainless Steel Stub End - SS Stub End Long Stub End & Short Stub End ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L | ||||||||||||

| Duplex Steel Stub End ASTM A 815 UNS NO S 31803 , S 32205. | ||||||||||||

| Nickel Alloy Stub End: Standard: |

• ASTM / ASME SB 336 |

• UNS 10276 (HASTELLOY C 276 Stub End) |

• UNS 2200 (NICKEL 200 Stub End ) |

•UNS 2201 (NICKEL 201 Stub End ) |

• UNS 4400 (MONEL 400 Stub End ) |

• UNS 8020 (ALLOY 20 / 20 Stub End ) |

• UNS 8825 INCONEL (825 Stub End ) |

• UNS 6600 (INCONEL 600 Stub End) |

• UNS 6601 (INCONEL 601 Stub End) |

• UNS 6625 (Inconel 625 Stub End) |

Value Added Services

• Hot Dip Galvanizing • Epoxy Coating • Electro polish

Test Certificate

Mill Test Certificate as per EN 10204 / 3.1B

| Nominal Pipe Size | Outside diameter of barrel |

Length (F) | Radius (R) | Diameter (G) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2" | 20.5 | 22.8 | 76 | 51 | 3 | 35 |

| 3/4" | 25.9 | 28.1 | 76 | 51 | 3 | 43 |

| 1" | 32.6 | 35.0 | 102 | 51 | 3 | 51 |

| 1 1/4" | 41.4 | 43.6 | 102 | 51 | 5 | 64 |

| 1 1/2" | 47.5 | 49.9 | 102 | 51 | 6 | 74 |

| 2" | 59.5 | 62.4 | 152 | 64 | 8 | 92 |

| 2 1/2" | 72.2 | 75.3 | 152 | 64 | 8 | 105 |

| 3" | 88.1 | 91.3 | 152 | 64 | 10 | 127 |

| 3 1/2" | 100.8 | 104.0 | 152 | 76 | 10 | 140 |

| 4" | 113.5 | 116.7 | 152 | 76 | 11 | 157 |

| 5" | 140.5 | 144.3 | 203 | 76 | 11 | 186 |

| 6" | 167.5 | 171.3 | 203 | 89 | 13 | 216 |

| 8" | 218.3 | 222.1 | 203 | 102 | 13 | 270 |

| 10" | 272.3 | 277.2 | 254 | 127 | 13 | 324 |

| 12" | 323.1 | 328.0 | 254 | 152 | 13 | 381 |

| 14" | 354.8 | 359.9 | 305 | 152 | 13 | 413 |

| 16" | 405.6 | 411.0 | 305 | 152 | 13 | 470 |

| 18" | 456.0 | 462.0 | 305 | 152 | 13 | 533 |

| 20" | 507.0 | 514.0 | 305 | 152 | 13 | 584 |

| 22" | 558.0 | 565.0 | 305 | 152 | 13 | 641 |

| 24" | 609.0 | 616.0 | 305 | 152 | 13 | 692 |

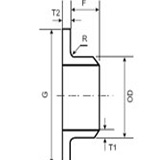

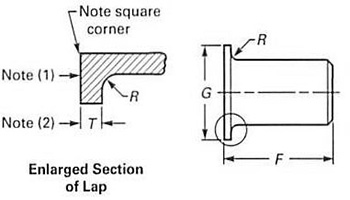

STUB ENDS – Ansi and MSS SP-43 dimensions

STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension |

|||||||

| inches | ND | mm | Diameter of lap | Radius of fillet |

Length F | ||

D |

G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

STUB ENDS – Ansi 16.9 tolerances

DIMENSIONAL TOLERANCES – STUB ENDS |

||||||

| For all fittings | Stub Ends | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Indide Ø at End | Wall Thickness t / t1 |

O.D. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | +0 -1 | +0 -1 | 2 |

| 3 a 3 1/2 | 1 | 1,6 | less | +0 -1 | +0 -1 | 2 |

| 4 | +2 -1 | 1,6 | than | +0 -1 | +0 -2 | 2 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | +0 -1 | +0 -2 | 2 |

| 8 | 2 | 1,6 | of nominal | +0 -1 | +0 -2 | 2 |

| 10 | +4 -3 | 3,2 | tickness | +0 -2 | +0 -2 | 2 |

| 12 to 18 | +4 -3 | 3,2 | +0 -2 | +0 -2 | 3 | |

| 20 a 24 | +6 -5 | 4,8 | +0 -2 | +0 -2 | 3 | |

| 26 a 30 | +7 -5 | 4,8 | ||||

| 32 a 48 | +7 -5 | 4,8 | ||||

STUB ENDS – Weights

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

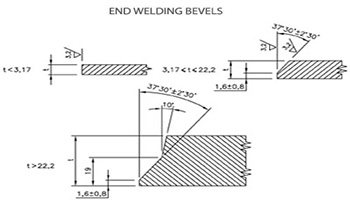

STUB ENDS – End welding bevels

| NOMINAL PIPE SIZE (Inches) | NB | OD | THICKNESS | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

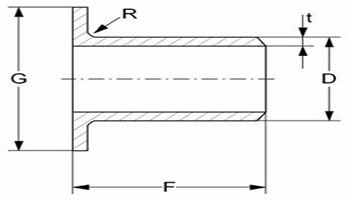

STUB ENDS SHORT LENGTH ASTM A403/A815 ASME B16.9

Facing: 125-250 RMS (smooth finish)

welded version = w

= s seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 " | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 " | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 " | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 " | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 " | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 " | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 " | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 " | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 " | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 " | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 " | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 " | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 " | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 " | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 " | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 " | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 " | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 " | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 " | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |

ALLOY GRADES

| ALLOY | Forging/ Flanges / Forged Fittings | Fitting / Tube Fitting / Buttweld Fitting |

|---|---|---|

| Hastelloy B-2 / B-3 | ASTM B564 | ASTM B366-WPHB2/3 |

| Hastelloy C-276 | ASTM B564 | ASTM B366-WPHC276 |

| Hastelloy C-4 | ASTM B564 | ASTM B366-WPHC4 |

| Hastelloy C-22 | ASTM B564 | ASTM B366-WPHC22 |

| Hastelloy C-2000 | ASTM B564 | ASTM B366-WPHG |

| Hastelloy G-3 | ASTM B564 | ASTM B366-WPHG3 |

| Hastelloy G-30 | ASTM B564 | ASTM B366-WPHG30 |

| Hastelloy X | ASTM B564 | ASTM B366WPHX |

| INCONEL 600 | ASTM B564 | ASTM B366-WPNCI |

| INCONEL 601 | ASTM B564 | ASTM B366 |

| INCONEL 617 | ||

| Inconel 625 | ASTM B446 | |

| INCONEL 690 | ||

| INCONEL 718 | ASTM B637 | |

| INCONEL X-750 | ASTM B637 | |

| INCOLOY 800 | ASTM B564 | ASTM B366-WPNIC |

| INCOLOY 800H | ASTM B564 | ASTM B366-WPNIC10 |

| INCOLOY 800HT | ASTM B564 | ASTM B366-WPNIC11 |

| INCOLOY 825 | ASTM B366-WPNICMC | |

| MONEL 400 | ASTM B564 | ASTM B366-WPNC |

| MONEL K-500 | ||

| NICKEL 200 | ASTM B366-WPN | |

| NICKEL 201 | ASTM B366-WPNL | |

| ALLOY 20 | ASTM B462 | ASTM B366-WP20CB |

| TITANIUM | ASTM B381 | ASTM B363-WPT(Gr) |

| ZIRCONIUM | ASTM B493 | ASTM B653-PZ(Gr) |

| TANTALUM | ||

| Cu-Ni 70/30 | ||

| Cu-Ni 90/10 | ||

| DUPLEX 2205 | A182F51 | A815 |

| 904 L |

| Are you interested in Great offers? valid on below stock | ||||

|---|---|---|---|---|

|

|

|

||

We are having our sub dealers & distributor with adequate stock of Stainless Steel Buttweld Fittings in India, United States, UK, Italy, Canada, UAE, Iran, South Korea, Indonesia, Saudi Arabia, Germany, Malaysia, Thailand, Venezuela, Spain, Mexico, Turkey, Poland, France, Australia, Singapore, Brazil, Netherlands, Russia, Vietnam, Colombia, Bangladesh, South Africa, Russia, Vietnam, Oman, Austria, Philippines, Qatar, Chile, China, Belgium, Zambia, Romania, China, Japan, Myanmar, Taiwan, Jordan, China, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar, Taiwan, Cambodia, Malta, Italy, United Kingdom (Uk), Spain, Ukraine, Netherland, The Republic Of Congo, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Israel, Czechia, Albania, Australia, Perth, Tanzania, Finland, Belgium, Greece, Czech Republic, Ireland, Croatia, Slovenia, Equatorial Guinea, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Switzerland, Slovakia, Tunisia, Nigeria, Algeria, Angola, South Africa, Libya, Gabon, Philippines & Sudan for quick delivery of Stainless Steel Buttweld Fittings with mill certificate & all required documents.

Origin : Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin

We offer fastest delivery of Stainless Steel Buttweld Fittings in Mumbai, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Kakinada, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Jamshedpur, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Haryana, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Pune, Thiruvanthapuram, Jaipur, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Salem, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Maharashtra, Tamil Nadu, Daman and Diu, Tripura, Gujarat, Manipur, Telangana, Delhi and Uttar Pradesh in India.